Corrosion Test Chamber

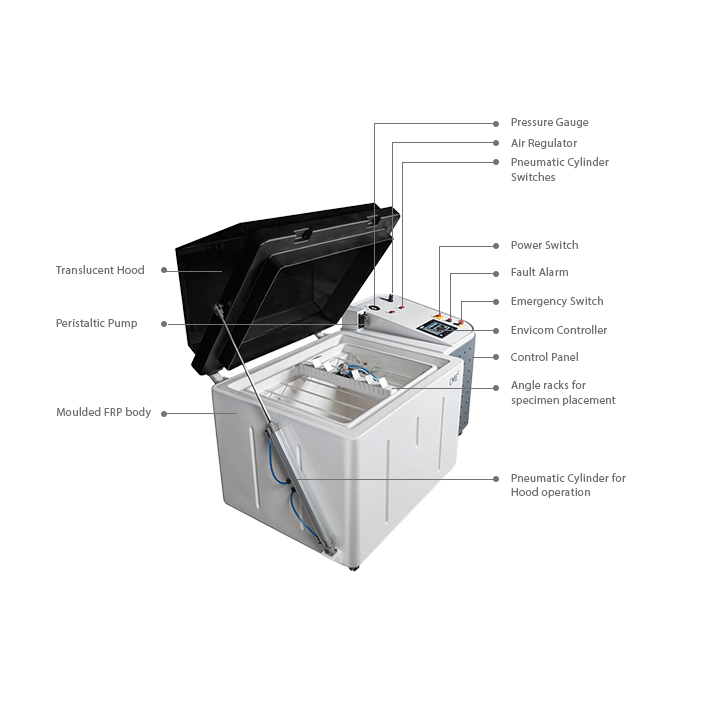

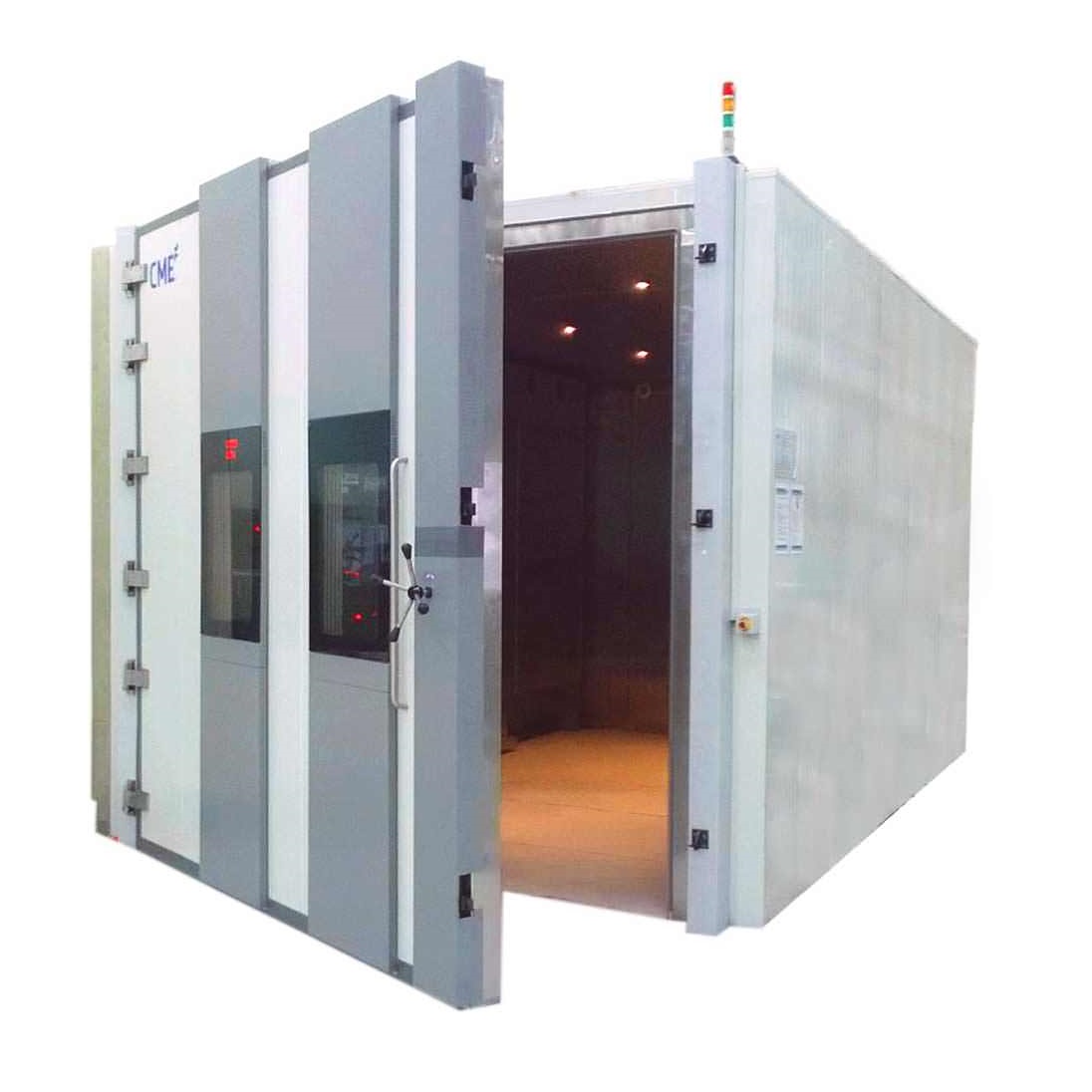

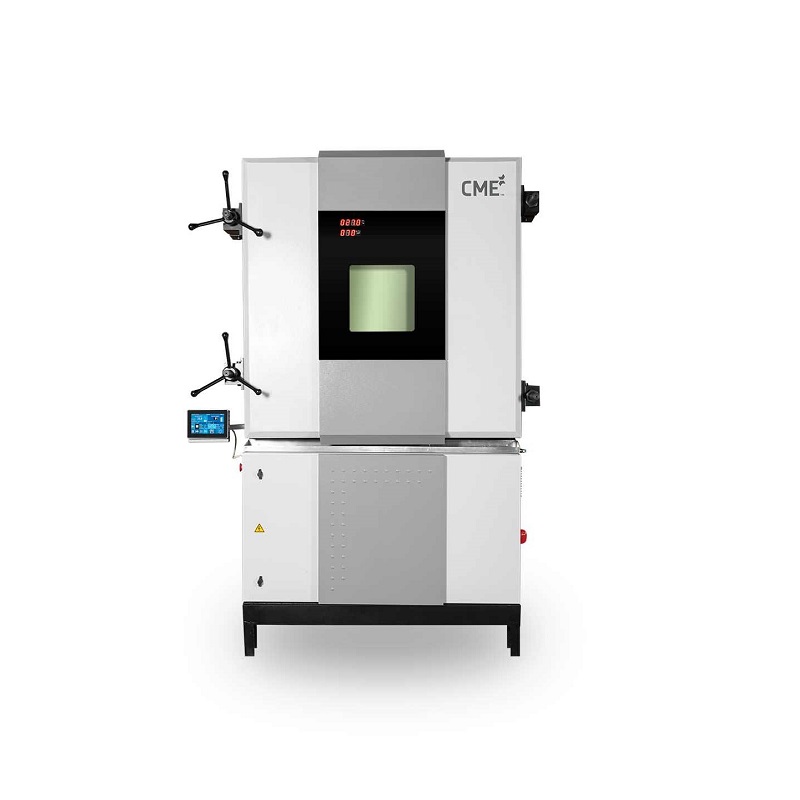

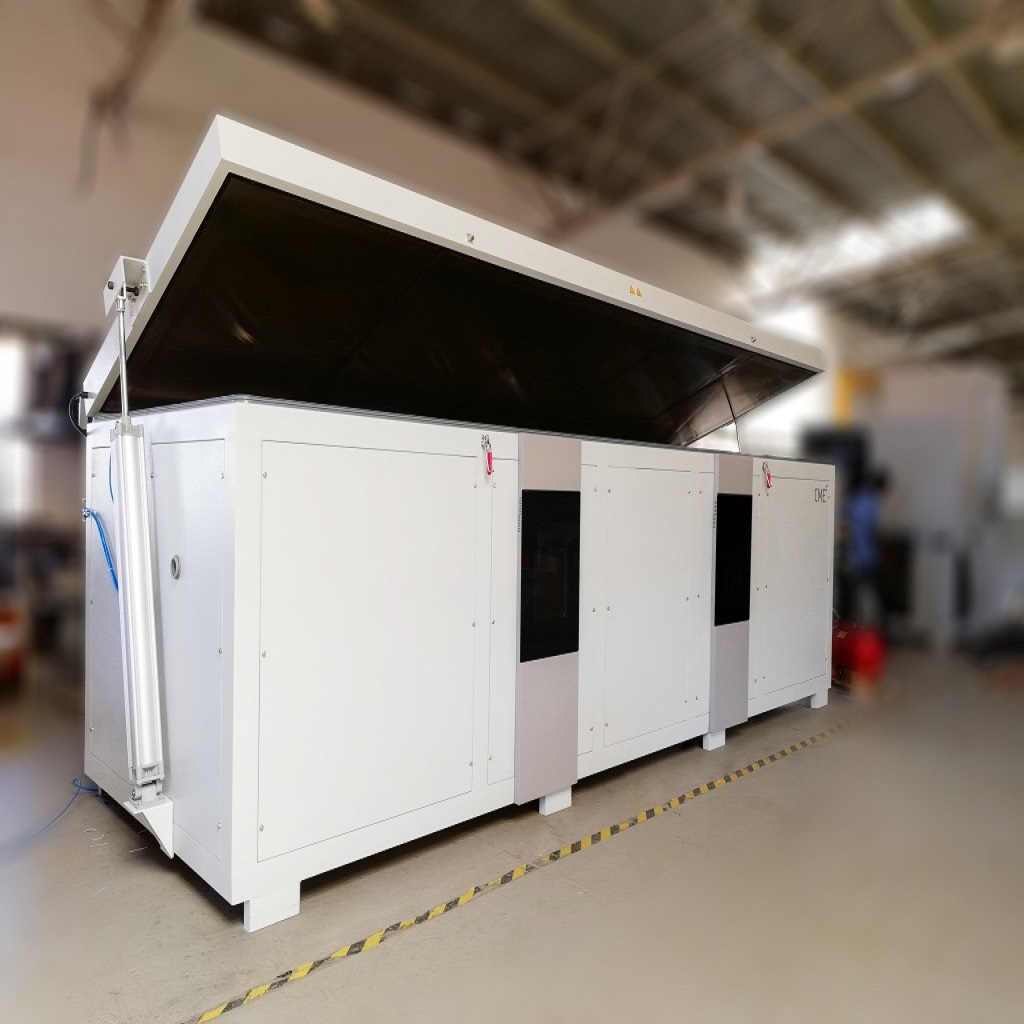

CME SF-CCT chambers are designed to be flexible enough to comply with as many different CCT specifications as possible. These may be programmed to conduct a whole range of corrosion tests such as wet cycle, dry cycle, controlled humidity as well as the salt spray test in a single chamber. This can occur in any sequence and be repeated automatically. A wide range of optional accessories enable additional climates to be added to further extend the number of climates and conditions that can be created.

CME SF-CCT chambers are designed to be flexible enough to comply with as many different CCT specifications as possible. These may be programmed to conduct a whole range of corrosion tests such as wet cycle, dry cycle, controlled humidity as well as the salt spray test in a single chamber. This can occur in any sequence and be repeated automatically. A wide range of optional accessories enable additional climates to be added to further extend the number of climates and conditions that can be created.

CME offer both a cyclic corrosion test chamber (SF-CCT) as well as a traditional salt spray chamber (SF-SST). The SF-CCT chambers are compatible with multiple test standards including automotive standards and they can be alternated/cycled between varied humidity programs with the traditional salt spray.

In recent years it has been proven that cyclic corrosion tests offer a more realistic simulation of real time corrosive environments than the traditional salt spray testing method. The salts spray test revolves around a single set point of temperature (ambient to 55oC) on the continuous mode. It lacks the role of real-life conditions. such as condensation humidity, air-drying etc. making the test less reliable than the cyclic corrosion test. Though CME offer both variants (cyclic corrosion test as well as salt spray test) of the chamber, it always suggests opting for SF-CCT as it is programmed to conduct a whole range of corrosion tests such as wet cycle, dry cycle, controlled humidity as well as the salt spray test in a single chamber.

Corrosion testing involves multiple test standards, which are developed by the automobile manufacturers or are according to the specific country standards. To match this diversity, CME has engineered both its SF-CCT as well as SF-SST to comply with more than 100 global test standards. It has a mix of all types of test standards ranging from ASTM, MIL, ISO, JASO to GM, NFX, AS, ECC and more.

Got Technical Question!

| Model Selection table | ||||||||||

| Specification | ||||||||||

| Units | SF-450-SST | SF-450-CCT | SF-1000-SST | SF-1000-CCT | ||||||

| Test Space Dimensions with Hood (wxdxh) |

mm In |

800 x 730 x 1300 [868 Ltrs] 31.5 x 29 x 51 [ 30.6 Cuft] |

1680 x 800 x 1400 [1678 Ltrs] 66 x 31.5 x 55 [59.2Cuft] |

|||||||

| Test Space Dimensions without Hood (wxdxh) |

mm In |

850 x 730 x 820 [519 Ltrs] 33.5 x 29 x 32 [18.3 Cuft] |

1680 x 800 x 890 [951 Ltrs] 66 x 31.5 x 35 [33.6 Cuft] |

|||||||

| External Dimensions (WxDxH) |

mm In |

1720 x 1080 x 1520 68 x 42.5 x 60 |

1720 x 1370 x 1520 68 x 54 x 60 |

2538 x 1155 x 1625 100 x 46 x 64 |

2538 x 1525 x 1625 100 x 60 x 64 |

|||||

| Temperature Range | °C °F |

5 above ambient to 55 41 above ambient to 131 |

5 above ambient to 70 41 above ambient to 158 |

5 above ambient to 55 41 above ambient to 131 |

5 above ambient to 70 41 above ambient to 158 |

|||||

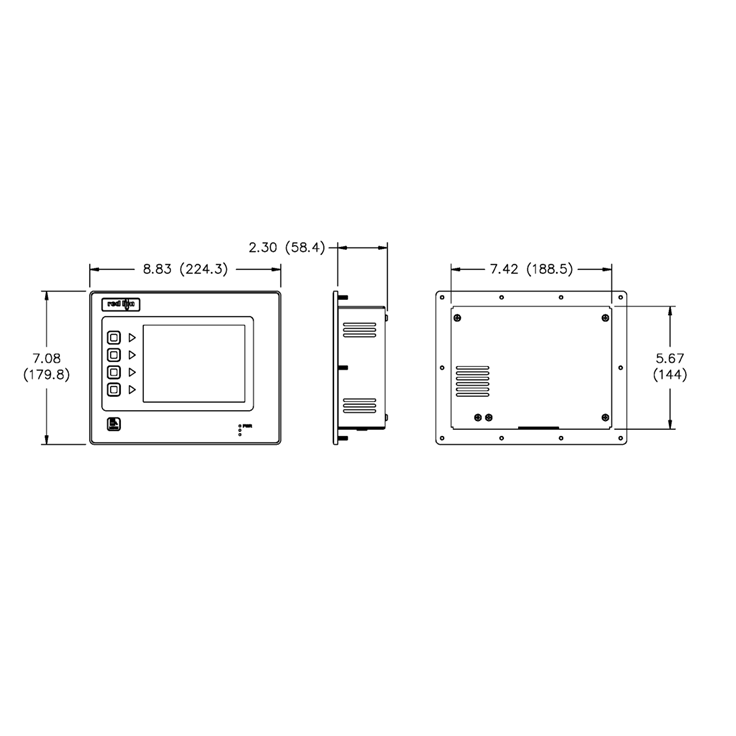

USB

A USB Type-B data port shall be provided to connect a PC for software upgrades or access the internal storage to download test data and diagnostics data.

Security

Two level security shall be provided to operate the controller.

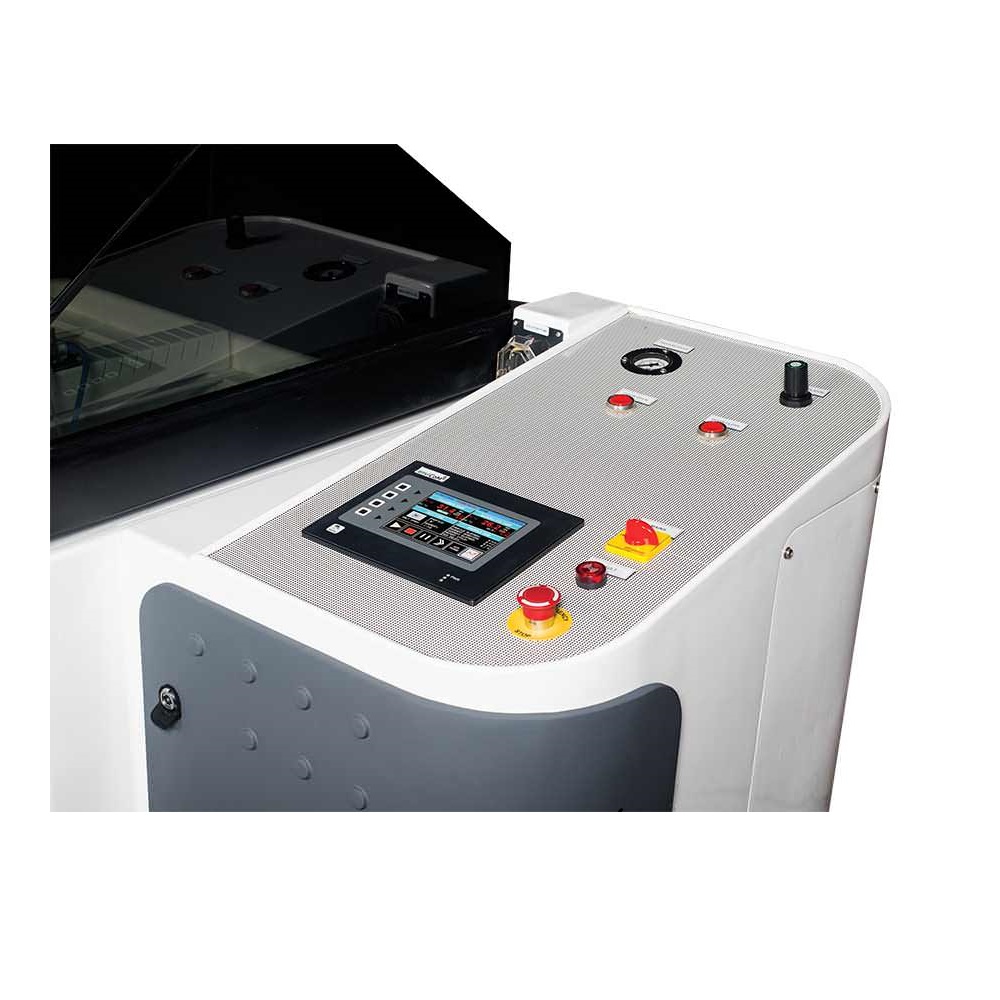

Touch Screen

The chamber shall be operated using a 5.7-inch TFT active matrix resistive analog touch screen. The screen shall have a 256 color QVGA, with a screen resolution of 320 x 240 pixel. The screen is mounted on the operating panel of the chamber.

Programs

The chamber shall have a program mode in the controller which shall have 99 independent programs. These programs can be stored with a name and number. Each of these programs shall have 30 segments where different modes such as salt spray, dwell, dry cycle, high humidity cycle, and air inlet can be set

Diagnostics

An event viewer shall display a log of all errors and actions with a date and time stamp. These events are also logged in a csv file which can be accessed using the USB or Ethernet ports available in the controller. The PLC’s digital inputs and outputs statuses shall be indicated to analyse the working of all the electrical components in the chamber. Alarm popups shall appear in the touch screen in case of any errors or alerts. The alarm shall be cleared by using the help information provided in the popup. A csv file of every test program shall be created and stored in the internal memory of the controller. The values that are logged, temperature percentage output, humidity percentage output, will be recorded.

Delay Start

A delay start of program shall be provided based on time, where the start of the program is scheduled. The delay schedule can be set for a maximum of 24h

Trend Graph

A real time trend shall be provided to view the test program in a graphical view. The parameters that shall be provided are include test space temperature process value, test space temperature set value, saturator temperature process value, saturator temperature set value humidity process value, humidity set value. Options of zoom in/out and pan shall be provided.

Web Server

A built-in web server shall be provided which allows remote view or control from any LAN, WAN or internet connected PC, tablet or smart phone. Any standard web browser shall allow access to the controller screens using the pre configured IP address. The screens on the web browser and the touch screen shall be duplicated to offer the same user interface / experience on PC or touchscreen.

Memory

The controller shall be provided with a SD card for the internal memory. The capacity of this memory shall be 2GB. The memory card shall store test program data and diagnostic data in csv format. This memory card shall be accessed using the USB and Ethernet ports.

PID

PID based control of temperature shall be provided in the controller. Each of these PID’s shall be set by using the auto tune feature or manually entered values.

Power Resumption

Various power resumption modes shall be provided in case of a power failure. The break mode shall stop the program on resumption of power. The hot mode shall resume the program from the point of break and complete the program. The cold mode shall restart the program from the point of break and ensure the program has run without any break

Process Mimic

A graphical representation of the working of the chamber shall be provided in the form of a process mimic screen. The live status of all major components are displayed. The components include heaters, valves etc.

Ethernet

A 10 Base T/100 Base-TX Ethernet connection shall be able to connect to an unlimited number of devices via ten protocols simultaneously. The Ethernet port is accessible through the controller by using a RJ45 port. The IP settings can be set in dynamic or static modes for access through LAN/WAN or the internet.