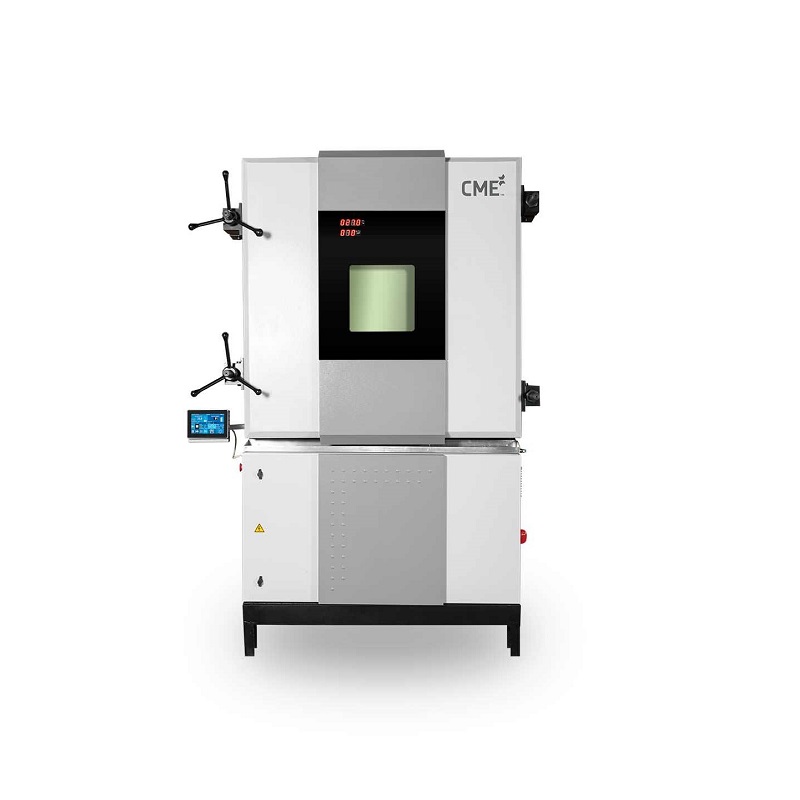

Basic Salt Spray Tester

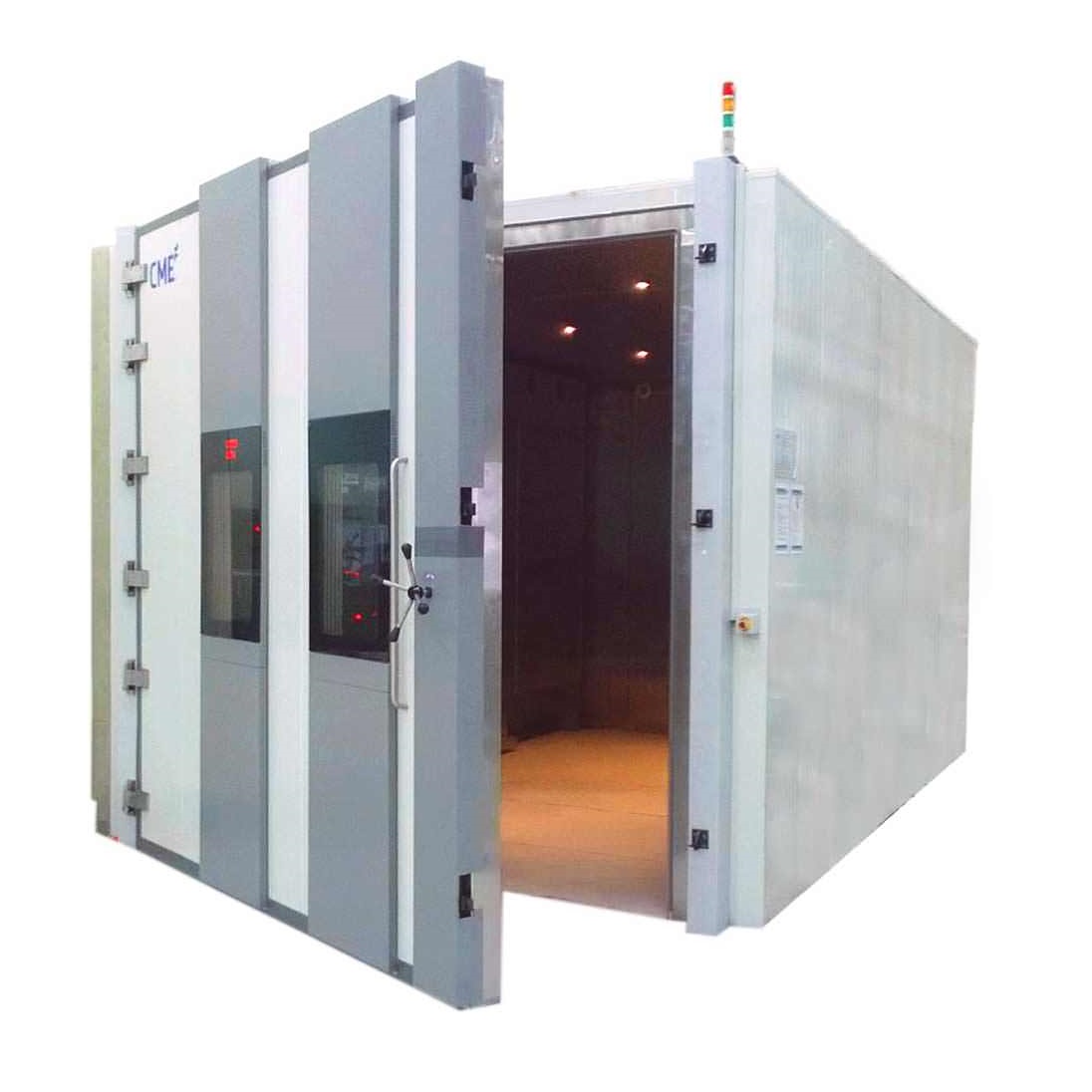

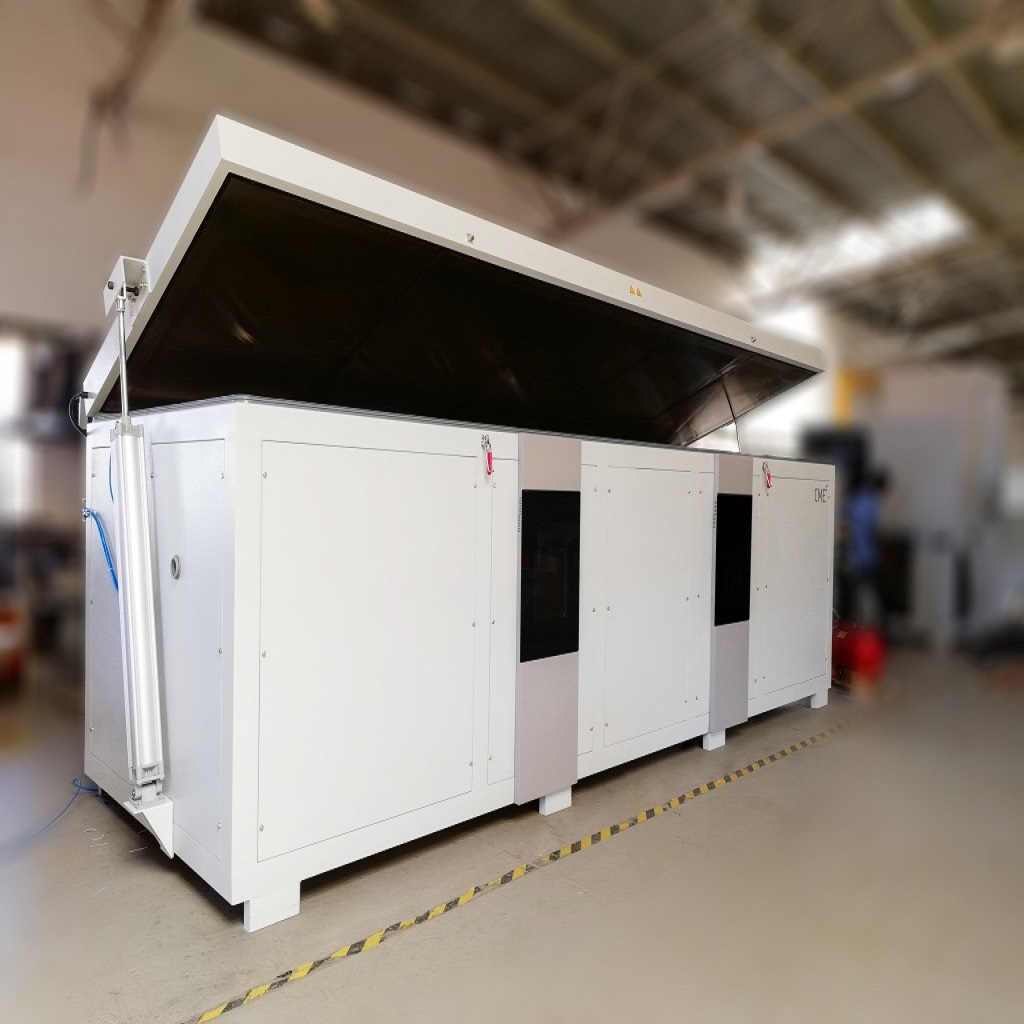

CME offer both a cyclic corrosion test chamber (SF-CCT) as well as a traditional salt spray chamber (SF-SST). The SF-CCT chambers are compatible with multiple test standards including automotive standards and they can be alternated/cycled between varied humidity programs with the traditional salt spray.

CME offer both a cyclic corrosion test chamber (SF-CCT) as well as a traditional salt spray chamber (SF-SST). The SF-CCT chambers are compatible with multiple test standards including automotive standards and they can be alternated/cycled between varied humidity programs with the traditional salt spray.

In recent years it has been proven that cyclic corrosion tests offer a more realistic simulation of real time corrosive environments than the traditional salt spray testing method. The salts spray test revolves around a single set point of temperature (ambient to 55oC) on the continuous mode. It lacks the role of real-life conditions. such as condensation humidity, air-drying etc. making the test less reliable than the cyclic corrosion test. Though CME offer both variants (cyclic corrosion test as well as salt spray test) of the chamber, it always suggests opting for SF-CCT as it is programmed to conduct a whole range of corrosion tests such as wet cycle, dry cycle, controlled humidity as well as the salt spray test in a single chamber

Corrosion testing involves multiple test standards, which are developed by the automobile manufacturers or are according to the specific country standards. To match this diversity, CME has engineered both its SF-CCT as well as SF-SST to comply with more than 100 global test standards. It has a mix of all types of test standards ranging from ASTM, MIL, ISO, JASO to GM, NFX, AS, ECC and more.

CME Salt Spray Test chamber meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS) or Cupric Acid (CASS) these are specified in ISO and other standards around the world. Salt spray tests are widely performed for various purposes such quality control and corrosion resistance comparison.

Got Technical Question!

| Model Selection table | ||||||||||

| Specification | ||||||||||

| Units | SF-450-SST | SF-450-CCT | SF-1000-SST | SF-1000-CCT | ||||||

| Test Space Dimensions with Hood (wxdxh) |

mm In |

800 x 730 x 1300 [868 Ltrs] 31.5 x 29 x 51 [ 30.6 Cuft] |

1680 x 800 x 1400 [1678 Ltrs] 66 x 31.5 x 55 [59.2Cuft] |

|||||||

| Test Space Dimensions without Hood (wxdxh) |

mm In |

850 x 730 x 820 [519 Ltrs] 33.5 x 29 x 32 [18.3 Cuft] |

1680 x 800 x 890 [951 Ltrs] 66 x 31.5 x 35 [33.6 Cuft] |

|||||||

| External Dimensions (WxDxH) |

mm In |

1720 x 1080 x 1520 68 x 42.5 x 60 |

1720 x 1370 x 1520 68 x 54 x 60 |

2538 x 1155 x 1625 100 x 46 x 64 |

2538 x 1525 x 1625 100 x 60 x 64 |

|||||

| Temperature Range | °C °F |

5 above ambient to 55 41 above ambient to 131 |

5 above ambient to 70 41 above ambient to 158 |

5 above ambient to 55 41 above ambient to 131 |

5 above ambient to 70 41 above ambient to 158 |

|||||

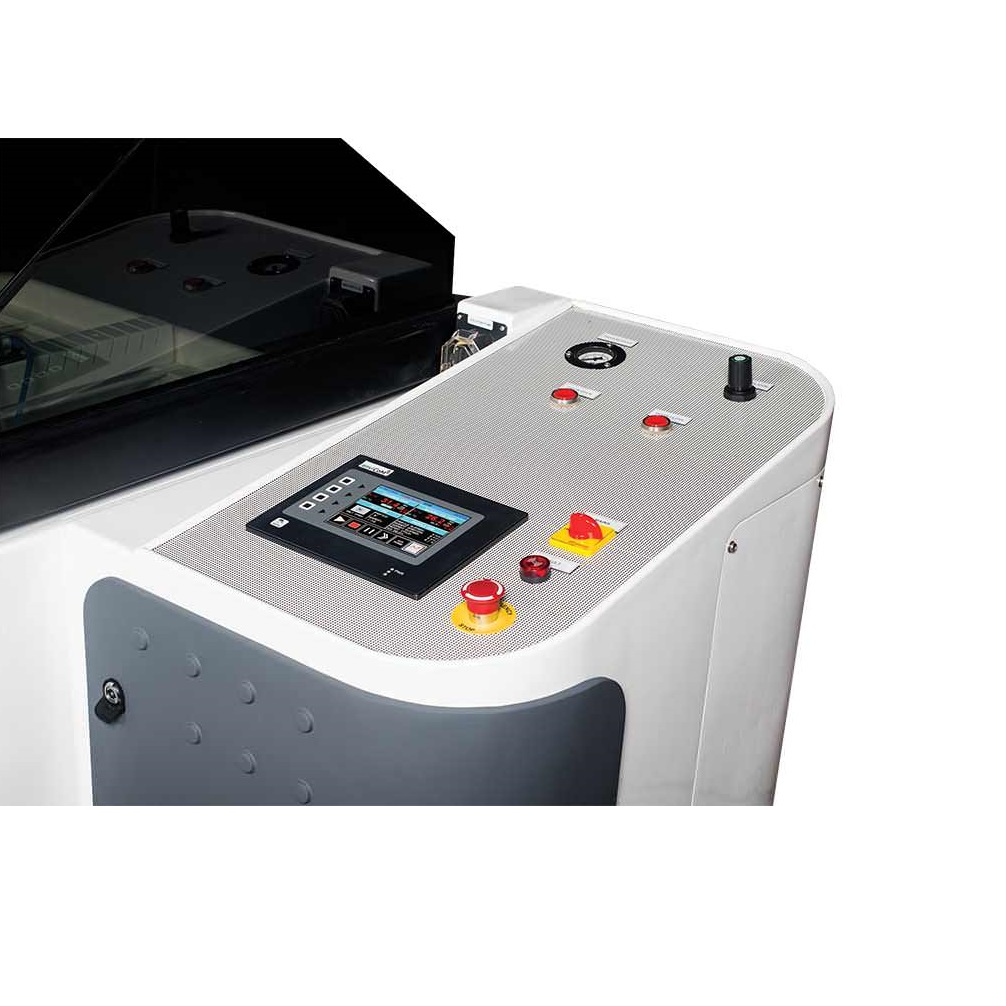

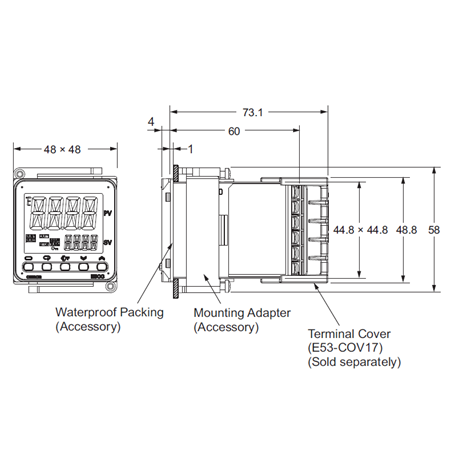

Test Space Controller

A digital temperature controller of 48x48mm size shall be used to control the temperature in the test space. The display shall be high contrast with LCDs displaying the process value in white and set value in green. Simple function keys shall be provided on the digital controller to change the set point. PID based control shall be used for precise control of the set point. RTD Pt-100 sensor will be used to connect this controller

Saturator Controller

A digital temperature controller of 48x48mm size shall be used to control the temperature in the saturator. The display shall be high contrast with LCDs displaying the process value in white and set value in green. Simple function keys shall be provided on the digital controller to change the set point. PID based control shall be used for precise control of the set point. RTD Pt-100 sensor will be used to connect this controller

Safety Controller

DIN mounted safety controllers shall be provided in the electrical compartment to connect the test space safety sensor and the saturator heater. The display shall be high contrast with LCDs displaying the process value in white and set value in green. Simple function keys shall be provided on the digital controller to change the limit. RTD Pt-100 sensor will be used to connect this controller

Cyclic Timer

A cyclic timer of 48x48mm shall be used to set the intervals of spray. The display shall be red LED and simple functions keys shall be provided to change the spray on/off time.