Tumbling Chamber for Ballistic Evaluation of Bullet Proof Jackets

A soldier’s most important means of preserving life and health are ballistic protection equipment such as a bulletproof jacket or helmet. Ergonomic is one of the important aspects of personal protection equipment which in this case is thermal stress caused using specific equipment. Testing (consists of three primary equipment one being CME’s Climatic Chamber) involves assessment of the Ballistic jacket’s thermal insulation properties to know what extent the jacket impedes the transmission of heat from the human body to its surroundings.

A soldier’s most important means of preserving life and health are ballistic protection equipment such as a bulletproof jacket or helmet. Ergonomic is one of the important aspects of personal protection equipment which in this case is thermal stress caused using specific equipment. Testing (consists of three primary equipment one being CME’s Climatic Chamber) involves assessment of the Ballistic jacket’s thermal insulation properties to know what extent the jacket impedes the transmission of heat from the human body to its surroundings.

It is very important that ballistic jackets should not only perform protective functions but also should not influence the users’ bodies negatively which generally occurs from both decreased energy loss from the human body and heat transfer disturbances due to the weight and size of the jacket, and the ambient temperature and level of physical effort required by the soldier. It’s difficult to a have a one perfect comfort guideline for all ballistic jackets because the user’s physiology and psychology as well as the external surroundings may differ. However by maintaining thermal balance near perfect ergonomics can be achieved. Environmental factors such as air temperature, radiation mean temperature, water vapour partial pressure and air flow speed; and individual factors such as the energy output related to the intensity of the work performed (otherwise called the metabolic rate), and the transfer of heat through clothes, also called clothing thermal insulation influences thermal balances.

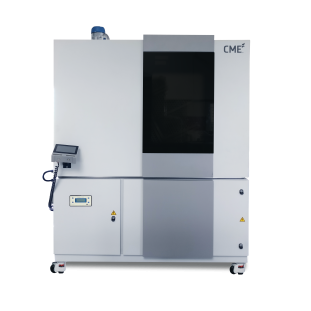

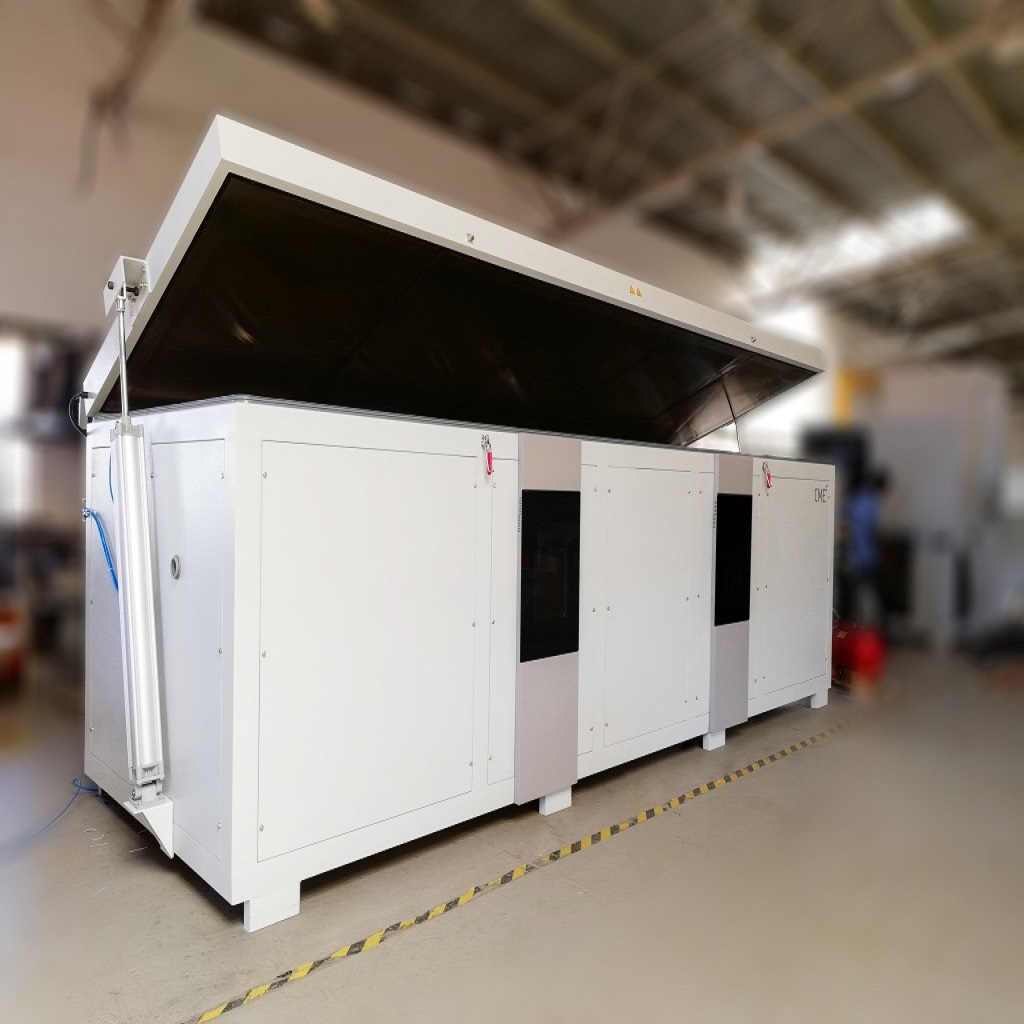

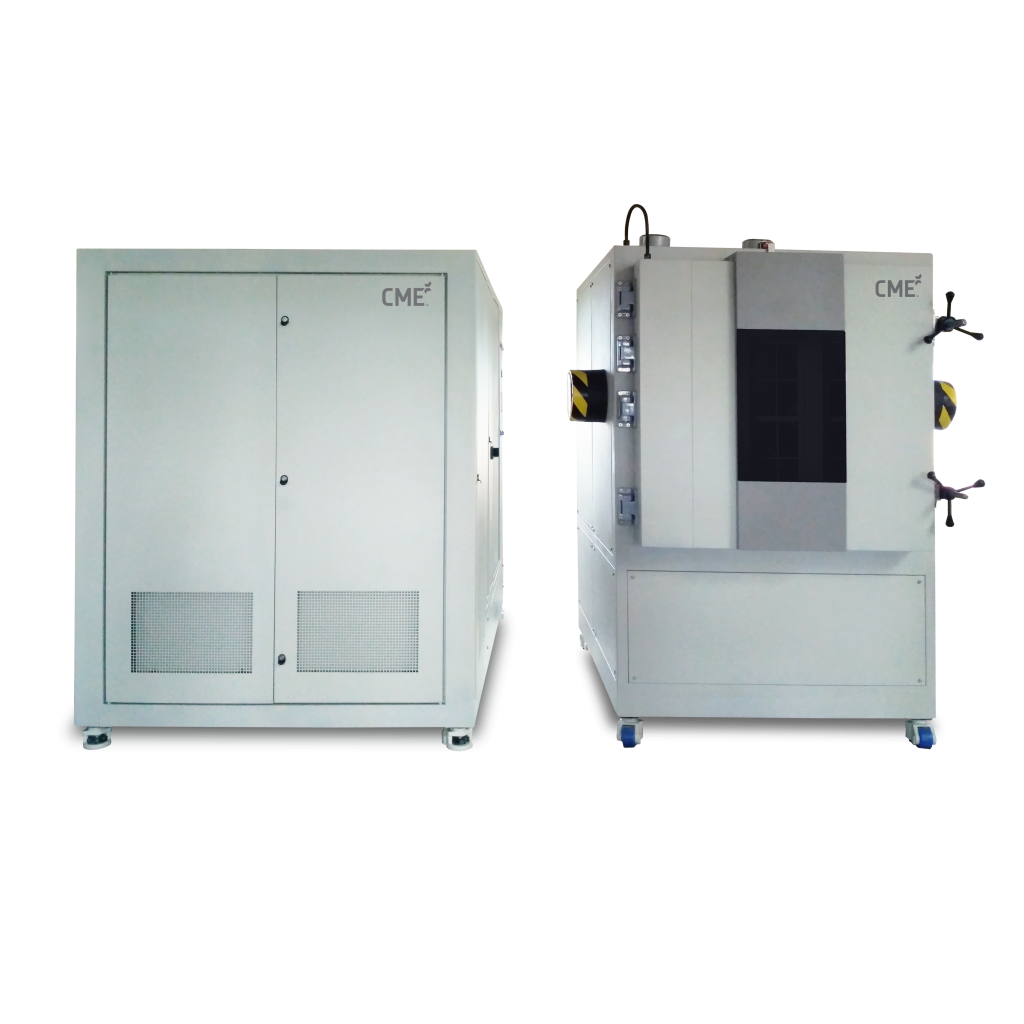

A series of test equipment are used to determine thermal insulation primary among them being Climatic Chamber. CME’s chamber used here offers working temperature range of -20 °C to 95 °C with humidity range of 10%RH to 98% RH while the capacity is 1000 Litres. The tests are performed according to the ISO 15831:2004 standard with sensors measuring air temperature and tumbling rpm.

Got Technical Question!

| Description | Specification | ||||

| Workspace Dimensions - WxDxH | |||||

| mm | 1000 | x | 1000 | x | 1000 |

| In | 39 | x | 39 | x | 39 |

| Volume | |||||

| Ltr | 1000 | ||||

| Cuft | 35 | ||||

| Temperature Range | |||||

| °C | -20 | To | 100 | ||

| °F | -4 | To | 212 | ||

| Ramp Rates | |||||

| Cooling °C/min | 5 | ||||

| Heating °C/min | 5 | ||||

Ethernet

Ethernet capability to remotely monitor and control the chamber.

USB

USB Type-A host port to connect a keyboard or mouse or download CSV data via pen drive [max 2GB] USB Type-B data port for connection to PC for software upgrade and access memory card storage

Web Server

Built-in web server allows remote view or control from any internet connected PC, tablet or smart phone

NI Lab view

The communication which used is MODBUS RTU protocol, which is an international standard for communication in process instrumentation and automation. Necessary changes to be made in the user’s software to communicate this in MODBUS RTU universal protocol. This feature can be used manual mode only.

Hardware

Enhanced with modular controller integrating multi-zone PID control and data acquisition. SIMATIC programmable logic controller. Touch screen controller, PLC and other controller components are of a generic make with an OEM software. Free software upgrades up to one year.

Memory

SD card of 2GB memory will store all the test program data and also the diagnostic data. This card is accessible by USB and Ethernet.

Digital Events

1 digital output for switching test specimen via potential free contacts, load max. 24 VDC, 5A

Programs

99 independent programs can be stored with name and number. Each of these programs have segments which can be looped to a previous segment and repeated up to 999 cycles, creating almost unlimited number of segments The chamber can be operated in manual mode, where the set point can directly be changed in the home screen The ramp rate can be set as a value in °C/min or ramp time Graphical representation of the temperature program The time is logged only when the set valve is within the band.

Trend Graph

Real time trend graph for temperature set value, temperature process value, humidity set value and humidity process value. Options of zoom in/out, pan and individual plot selection

Security

Multi level security of guest, user, admin and factory level users with individual password protection All settings can be reset to factory defaults using admin login

PID

6 zone based PID’s with auto recall of PID based on type of program, segment and zone can be set. Each of these PID’s can be set by using the auto tune feature or manually based on user’s requirements.

Process Mimic

Graphical representation of the working of the chamber, with live status of all the components, including the current temperature/humidity process values, compressor suction/discharge pressures and return gas temperature

Power Resumption Modes

In case of a power failure, option of conditional restart based on temperature/time or continuous

Diagnostics

Event viewer will display a log of all errors/actions with a date and time stamp PLC inputs and outputs status will be indicated

Service Monitor

Log of critical components life cycle with a predefined life cycle time and elapsed time in hours

Delay Start

Real time clock based, delayed start function