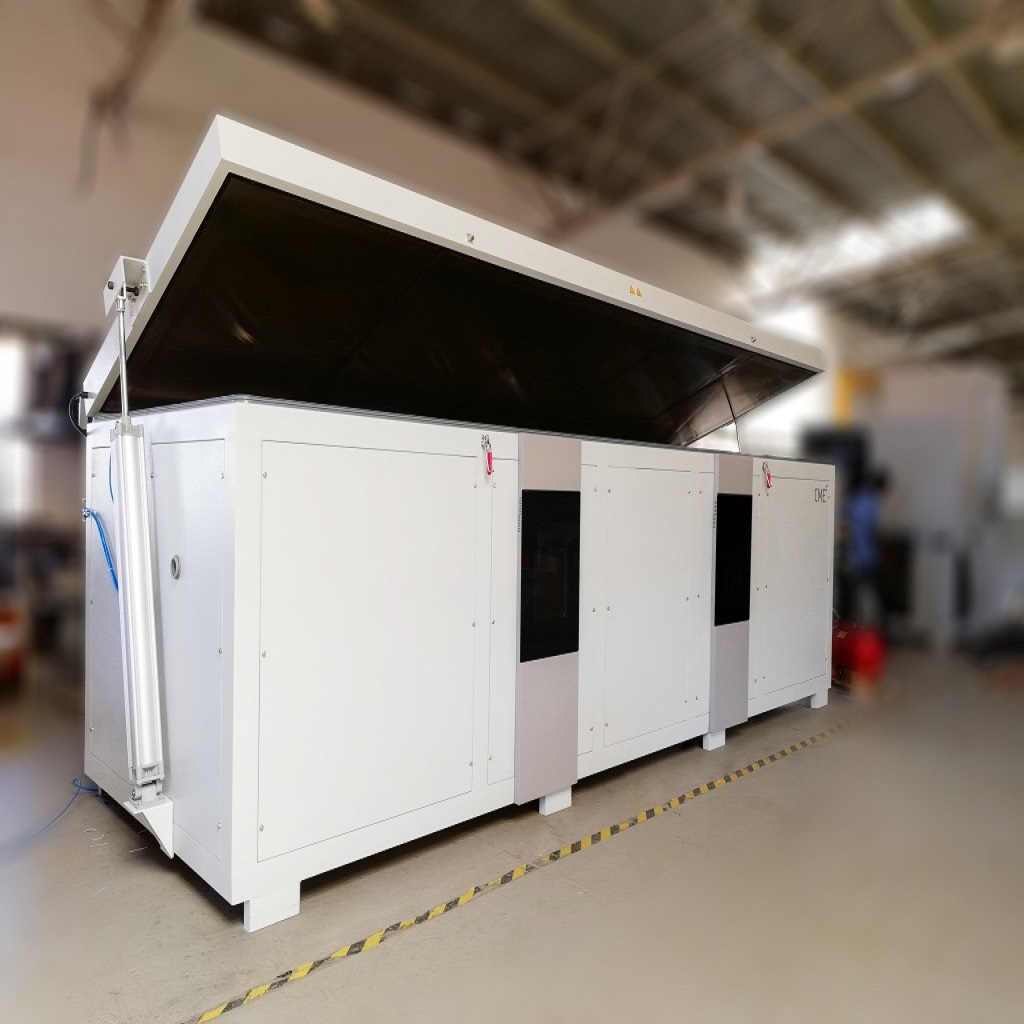

Climatic Chamber for Explosives Testing (ISAT)

It is essential to determine the performance of various explosive filled components and their shelf-life during defence product development. Tests involving tropical exposure and intensified standard alternating trials (ISAT) are norm of such performance evaluation process and our customised Climatic Chamber is designed to do it with ease. The 7,200 litre chamber can perform both ISAT (A) & ISAT (B) tests which is based on the alternations between temperature, humidity and ambient conditions (with condensation) and has a small element i.e. each week of dry heat to simulate tropical desert.

It is essential to determine the performance of various explosive filled components and their shelf-life during defence product development. Tests involving tropical exposure and intensified standard alternating trials (ISAT) are norm of such performance evaluation process and our customised Climatic Chamber is designed to do it with ease. The 7,200 litre chamber can perform both ISAT (A) & ISAT (B) tests which is based on the alternations between temperature, humidity and ambient conditions (with condensation) and has a small element i.e. each week of dry heat to simulate tropical desert.

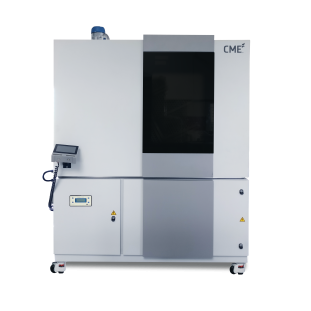

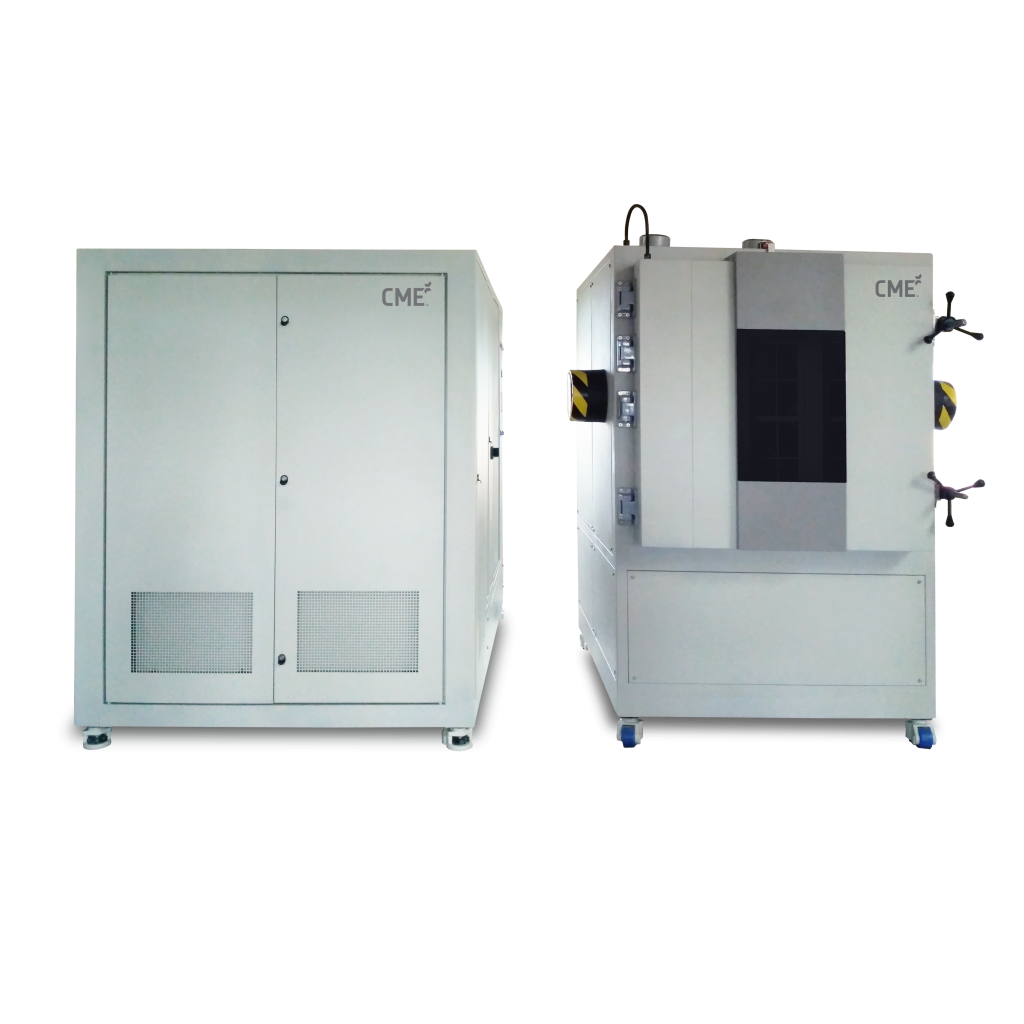

The monoblock construction has outer material primed with phosphate while RAL 7035 epoxy based electrostatic powder coating provides aesthetic look. The exterior surface has high wear resistance while the interior is made of pre-polished stainless steel with high gloss finish (1.2 mm thick) AISI-304 stainless steel with reinforce bottom floor to withstand heavy load. Between cell-wall and the outer house approximately 150mm PUF is provided. A large observation window is provided which is illuminated by a lamp to provide good test space view. Explosion proof fitting are used in chamber construction to meet IP55 regulation which are also impermeable and thermally isolated. Double construction sealing rings of silicon rubber is mounted on a thermal breaker strip to ensure complete sealing and zero conduction from the test space to the exterior.

Chamber’s performance is evident from its uniform air and temperature distribution while its humidity range makes it compatible to test as per many of the latest test standards. Although ISAT was originally designed for ordnance ammunition and small arms reliability testing but now plays significant role in rocket component testing especially in rocket motors. It has been of special value as a test of igniter designs because of the potentially bad effects of moisture on igniter compositions.